More Sewing Contractor Companies

Sewing contractors are specialized companies providing a broad spectrum of sewing and garment manufacturing services, including custom sewing, pattern-making, industrial cutting, and sewing assembly. These contract sewing services deliver high-quality results for clients in industries such as fashion, apparel manufacturing, home textiles, automotive upholstery, medical textiles, defense, promotional products, outdoor gear, and more. By leveraging the expertise of experienced contract garment manufacturers, businesses benefit from streamlined production, cost savings, and the ability to scale operations efficiently—even when handling complex projects or fluctuating demand.

Sewing Contractor Products

Sewing contractors manufacture an extensive array of textile and sewn products, tailored to meet the unique demands of various sectors. In the aerospace and aircraft industry, they produce safety-critical items such as ground service covers, thermal blankets, carpets, upholstery, and specialized airplane seating. For commercial environments, including amusement parks, retail stores, banking, and logistics, sewing contractors fabricate durable courier bags, transit cases, security bags, and tamper-evident pouches.

The range of custom sewn goods extends to general fabric items like custom bags, pouches, soft-sided luggage, fitted and unfitted protective covers, and equipment wraps. Custom bags are meticulously designed to customer specifications, considering material selection, size, and intended use—whether for consumer electronics, industrial tools, or specialty sports gear. These made-to-order solutions ensure optimal protection, functionality, and aesthetics.

Pouches are among the most requested contract sewing items, ideal for safely carrying manuals, medical supplies, infusers, flags, camera equipment, cables, batteries, and automotive accessories. Soft luggage, crafted from robust materials such as canvas, ballistic nylon, or genuine leather, can be sized for carry-ons or large check-in pieces. This versatile category includes sports bags, duffels, briefcases, and backpacks, which offer lightweight, organized alternatives to hard-shell suitcases. Secure closures—zippers, clasps, buttons, or hook-and-loop fasteners—are selected for durability and convenience.

Protective covers, a staple of industrial sewing services, are made from heavy-duty canvas or nylon coated with paint, tar, or weatherproofing agents. These covers shield valuable items from water, dust, UV rays, and other environmental hazards—making them indispensable for dumpsters, vehicles, outdoor furniture, machinery, and grills. Many contract sewing companies also supply custom-fitted tarps and covers for marine, agricultural, and construction equipment.

Unfitted covers, such as tarps, serve multiple purposes: shielding swimming pools, safeguarding vehicles during storage and transport, protecting machinery, and acting as ground cloths or tent floors in camping and outdoor settings. Their versatility and resilience make them essential for both commercial and recreational applications.

Are you searching for specific types of sewn products or have a unique project requirement? Explore our complete list of sewing contractor companies to find a partner with the right expertise for your application.

History of Sewing Contractors

Sewing has been integral to human society for millennia, evolving from primitive hand-stitching with bone and sinew to sophisticated, mechanized production processes. Early garment and textile production relied heavily on skilled artisans, with sewing performed in the home or by local craftsmen. Manual sewing was not only labor-intensive but also demanded high levels of dexterity and patience.

The Industrial Revolution marked a turning point in the textile and apparel manufacturing industry. In 1790, Thomas Saint introduced the first mechanical sewing machine in London, followed by notable enhancements from inventors like Barthélemy Thimonnier, who gained several patents between 1830 and 1847. Despite his innovation, Thimonnier did not achieve commercial success, but his groundwork paved the way for future advancements.

The breakthrough came in 1851 with Isaac Singer’s patented sewing machine, which dramatically increased sewing speed and consistency—up to 900 stitches per minute compared to the manual pace of 40. This leap in productivity revolutionized both industrial and domestic textile manufacturing, enabling mass production and the rise of ready-to-wear clothing and accessories.

Manufacturers such as Singer quickly scaled up, mass-producing sewing machines for factories and households. The adoption of industrial sewing machines—capable of handling multiple layers, heavy fabrics, and complex stitching—shifted the locus of textile production from individual seamstresses and tailors to large-scale sewing contractors and factories. This transition fueled the growth of the global apparel, home furnishing, and sewn goods industries.

Today, modern sewing contractors leverage advanced technologies, computer-aided design (CAD), automated cutting machines, and high-performance synthetic fabrics to tackle complex projects. From developing flame-retardant military gear to medical-grade bags and custom sports equipment, contract sewing companies meet stringent regulatory and performance standards, positioning themselves as industry leaders in innovation and quality.

Curious about how sewing contractors have shaped today’s textile industry? Learn more about the history and evolution of contract sewing and discover leading companies in your region.

Materials for Sewing Contractors

Sewing contractors utilize a comprehensive selection of high-performance materials, each chosen for its unique properties and suitability for specific applications. The choice of textiles, fabrics, and components is crucial in achieving the desired durability, appearance, compliance, and cost-effectiveness for every sewn product.

- Vinyl-Coated Nylon: Highly durable, lightweight, and weather-resistant, this material is commonly used for protective covers, heavy-duty bags, and industrial cases. Its resistance to abrasion and moisture makes it ideal for demanding environments.

- Neoprene: Known for its flexibility, chemical resistance, and insulation, neoprene is widely used in the production of wetsuits, protective sleeves, orthopedic braces, and outdoor gear. Its affordability and versatility make it a contractor favorite, though it is not highly breathable.

- Hypalon: A synthetic rubber with exceptional resistance to abrasion, UV light, and chemicals, Hypalon excels in applications demanding superior performance, such as marine covers, inflatable boats, and industrial containment solutions.

- Canvas: A classic, breathable textile made from various fibers, including cotton and blends. Canvas is favored for its strength and versatility, making it the top choice for custom bags, tents, curtains, and durable workwear.

- Anti-Static Materials (ESD Fabric): Essential for the electronics and semiconductor industries, anti-static materials prevent static discharge that could damage sensitive components. ESD-compliant sewing contractors are in high demand for producing cleanroom garments, protective bags, and technical covers.

- Cotton: A naturally soft, absorbent, and versatile fabric. Cotton is prized for its comfort, easy care, color retention, and suitability for garments, bedding, and promotional textiles. It can be processed for enhanced strength and printed with custom designs.

- Polyester: This synthetic fabric offers excellent strength, chemical and mildew resistance, wrinkle resistance, and adaptability for both woven and nonwoven applications. Polyester is used extensively in apparel, luggage, industrial covers, and outdoor furniture due to its durability and quick-drying properties.

- Felt: Produced by compressing and matting fibers (often wool or synthetic), felt delivers a dense, nonwoven structure ideal for padding, insulation, crafts, and industrial gaskets. Its resilience and shock-absorbing qualities make it popular in both fashion and manufacturing.

- Plastic (Polymers): Ranging from nylon to polypropylene, plastics are increasingly incorporated into contract sewing for items like parachutes, tents, flags, and technical apparel. Their lightweight, waterproof, and moldable properties open up innovative product design possibilities.

- Webbing: Made from woven polyester, polypropylene, nylon, or specialty fibers like Kevlar, webbing delivers exceptional strength and load-bearing capacity. Flat webbing is standard for straps and seatbelts, while tubular webbing is preferred for climbing, rescue, and industrial rigging.

- Leather: Renowned for its durability, tear resistance, and luxurious feel. Leather is used in premium jackets, shoes, upholstery, and bookbindings. Contract sewing with leather requires specialized machinery and skilled craftsmanship to achieve top-quality results.

Selecting the right material is vital for the success of your sewn product. Need advice on which fabric or textile is best for your application? Connect with our featured sewing contractors for expert recommendations and material sourcing solutions.

Working with Sewing Contractors

Engaging a sewing contractor is a strategic decision that can transform your product development and manufacturing process. The collaboration typically begins with a comprehensive consultation, where the contractor learns about your project goals, technical requirements, target market, and budget constraints.

A pattern designer or CAD specialist creates detailed blueprints, incorporating precise measurements, seam placements, and material specifications. Prototyping is an essential next step—contract sewing companies often provide initial samples or prototypes for client evaluation and approval, ensuring alignment with your vision before scaling production.

Upon approval, contractors manage every phase of production: material sourcing, precision cutting (manual or automated), sewing, embroidery, assembly, and finishing. Services may include custom fitting, free prototypes, logo embroidery, and the manufacturing of custom clothing labels. Modern sewing contractors can integrate branding elements such as woven tags, embroidered logos, and printed care instructions—using materials like satin, taffeta, or damask.

Quality assurance is central to the contract sewing process. Many contractors adhere to strict industry standards, including ISO certification, FDA compliance for medical textiles, or military specifications (MIL-SPEC) for defense projects. Regular inspections and testing help ensure consistent quality and regulatory compliance.

Wondering how to get started with a sewing contractor? Ask about their minimum order quantities (MOQs), lead times, material sourcing capabilities, and experience with your specific product type.

Sewing Contractor Machinery

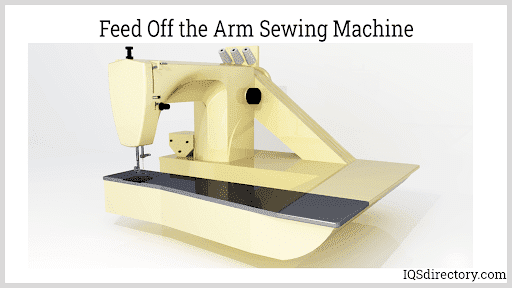

Industrial sewing contractors deploy a diverse array of sewing machinery and production equipment to deliver precise, efficient, and scalable results. Understanding the types of machinery used can help you evaluate a contractor’s capabilities and match them to your project requirements.

- Straight Stitch Machines: The workhorse of the industry, suitable for most standard seams and assemblies.

- Serger (Overlock) Machines: Provide durable edge finishes and prevent fabric fraying, essential for garment and upholstery production.

- Blind Stitch Machines: Used for invisible hems, creating a clean, professional look in apparel and drapery.

- Lockstitch and Chain Stitch Machines: Offer strong, flexible seams for garments, bags, and technical textiles.

- Overedge, Walking Foot, and Needle Feed Machines: Designed for thick, multi-layered, or slippery fabrics; ideal for heavy-duty sewing tasks.

- Double Needle, Zigzag, and Cylinder Arm Machines: Support decorative or reinforcement stitching, circular sewing, and complex shapes.

- Bar Tack, Box Tack, and Hook-and-Loop Fastener Machines: Used for reinforcing stress points in straps, handles, safety gear, and closures.

Industrial sewing machines are engineered for high speed, heavy use, and minimal downtime. They feature robust motors, automatic lubrication, and can accommodate specialty attachments for embroidery, digital cutting, screen printing, and ultrasonic welding. Maintenance is typically managed by on-site mechanics to keep production running smoothly.

Do you need specialized sewing techniques or advanced machinery for your project? Ask contractors about their machine fleet, automation capabilities, and support for custom attachments or processes.

Benefits of Sewing Contractors

Partnering with a professional sewing contractor unlocks numerous advantages for businesses seeking to optimize their manufacturing workflow, control costs, and deliver superior products to market. Here are key benefits that sewing contractors offer:

- Expertise and Specialization: Contractors bring years of experience, technical know-how, and industry certifications, ensuring top-tier craftsmanship and adherence to best practices.

- Cost Efficiency: By outsourcing sewing operations, companies avoid the capital expense of purchasing machinery, maintaining facilities, and hiring/training sewing staff. This reduction in overhead translates to better margins and competitive pricing.

- Scalability and Flexibility: Sewing contractors can rapidly adjust production volumes in response to changing demand, seasonal fluctuations, or new product launches. This agility is critical for businesses in fast-paced markets.

- Access to Advanced Technology: Contractors invest in the latest sewing machines, automation, and software, delivering greater precision, consistency, and efficiency than most in-house setups can achieve.

- Quality Control and Compliance: Stringent quality assurance processes and compliance with regulatory standards (such as ISO, FDA, or MIL-SPEC) ensure your products meet or exceed market expectations.

- Diverse Service Offerings: From prototyping and short runs to high-volume manufacturing, contract sewing companies can tackle projects of any size and complexity, supporting both established brands and startups.

- Streamlined Supply Chain: Contractors often manage sourcing, logistics, and inventory, reducing your administrative burden and ensuring timely delivery.

Ultimately, sewing contractors enable businesses to focus on core competencies such as design, marketing, and sales—while leaving the intricacies of textile production to industry specialists. This partnership model helps accelerate time-to-market, improve product quality, and support business growth.

Ready to boost your production efficiency and product quality? Contact a sewing contractor today to discuss your project requirements and request a quote.

Sewing Contractor Services

Selecting the right sewing contractor services starts with a clear understanding of your project needs and business goals. Consider the specific products you require—garments, technical textiles, medical devices, automotive upholstery, promotional merchandise, or industrial covers—and identify the critical sewing and assembly steps involved.

Production volume is another vital factor. If your business faces variable, seasonal, or fluctuating demand, choose a contractor with proven capacity for flexible scaling and short turnaround times. For steady, high-volume production, look for a partner with extensive manufacturing infrastructure and a track record of timely, consistent delivery.

In-house capabilities also play a role. If your company excels at design and pattern-making but lacks specialized machinery or labor for mass production, a contract sewing partner can bridge that gap. Many contractors offer value-added services such as design consultation, supply chain management, packaging, and fulfillment—helping you streamline operations from concept to customer delivery.

Additionally, evaluate a contractor’s experience in your target market or application. For example, medical device sewing requires knowledge of FDA-compliant cleanroom standards, while military and outdoor gear demand expertise in technical fabrics and reinforced construction.

Looking to diversify your product line or launch a new collection? Ask sewing contractors about their R&D, prototyping, and small-batch production services to support innovation without upfront risk.

Things to Consider

If you’re in the market for custom textiles, garments, or sewn components, it’s crucial to perform due diligence when selecting a sewing contractor. Begin by creating a detailed list of your project specifications, including:

- Product type and end-use application

- Environmental and performance requirements (e.g., waterproofing, flame resistance, antimicrobial properties)

- Dimensions, material preferences, and color options

- Volume requirements and anticipated order frequency

- Timeline, delivery preferences, and shipping logistics

- Budget constraints and target cost per unit

- Industry or regulatory standards (ISO, FDA, MIL-SPEC, etc.)

With your requirements in hand, review the companies listed on this page—each is recognized for industry expertise and innovative sewing solutions. Reach out to three or four contractors who best match your needs and request detailed proposals. Compare their capabilities, customer service, quality assurance processes, lead times, and pricing structures to make an informed decision.

Want to know what to ask a prospective sewing contractor? Inquire about their experience with similar products, sample turnaround times, minimum order quantities, and references from previous clients.

For further guidance or to explore other manufacturing solutions:

- Check out our Carrying Cases website

- Visit our Industrial Ovens website

Still have questions about selecting the ideal sewing contractor for your business? Contact us or browse our expanded directory of sewing contractor companies for more information, expert advice, and tailored solutions for your next project.

What services do sewing contractors provide?

Sewing contractors offer a wide range of services, including custom sewing, pattern making, industrial cutting, sewing assembly, prototyping, embroidery, manufacturing of custom clothing labels, and the production of custom bags, pouches, protective covers, soft-sided luggage, and specialized textile products for industries such as fashion, automotive, medical, defense, and more.

What types of products can sewing contractors manufacture?

Sewing contractors manufacture a diverse array of products including custom bags, pouches, soft-sided luggage, fitted and unfitted covers, tarps, industrial wraps, ground service covers, transit cases, security bags, upholstery, and specialized items for aerospace, medical, and commercial applications. They also produce garments, technical textiles, and promotional products.

Which materials are commonly used by sewing contractors?

Sewing contractors work with a variety of materials such as vinyl-coated nylon, neoprene, Hypalon, canvas, anti-static fabrics, cotton, polyester, felt, plastics, webbing (nylon, polyester, Kevlar), and leather. The choice of material depends on the product’s use, durability, performance requirements, and desired appearance.

How do I choose the right sewing contractor for my project?

To choose the right sewing contractor, assess your product specifications, performance requirements, materials, order volume, delivery timeline, budget, and industry standards. Request proposals from several contractors, compare their capabilities, quality assurance measures, lead times, and pricing, and check references and experience with similar projects.

What machinery do sewing contractors use for production?

Sewing contractors utilize industrial machinery such as straight stitch machines, serger (overlock) machines, blind stitch machines, lockstitch and chain stitch machines, walking foot and needle feed machines, double needle and zigzag machines, cylinder arm machines, and specialized equipment for bar tack, box tack, embroidery, digital cutting, and screen printing.

What are the benefits of working with a sewing contractor?

Working with a sewing contractor offers advantages such as access to specialized expertise, cost savings, scalability, advanced machinery, strict quality control, compliance with industry standards, and supply chain management. This collaboration enables businesses to focus on core functions while ensuring reliable product quality and timely delivery.

What should I ask a sewing contractor before starting a project?

You should ask about their experience with similar products, minimum order quantities (MOQs), lead times, material sourcing capabilities, quality assurance processes, regulatory compliance, machinery capabilities, and request references from previous clients to ensure they can meet your project’s needs.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services