When considering the many types of soft bags available, size, function, weight, additional accessories, cargo and type of travel all help to determine what bag is best suited to a given situation. Although the amount of give varies, flexible fabric allows bags to be packed slightly above normal capacity. This particular type of luggage is also relatively lightweight as compared to its rigid counterpart. Read More…

CustomFab USA has been a trusted American sewing contractor since our inception in 1990. Our 77,000 square foot high-tech manufacturing facility allows us to produce and ship a myriad of products. We have experience serving industries such as medical, sporting goods, military, aerospace, pets, and travel. With unparalleled customer service, a skilled manufacturing workforce, and tried-and-true...

LJ Design & Manufacturing's unique expertise in sewn, soft good product design and manufacturing turns your challenges into opportunities. They specialize in manufacturing sewn industrial and medical products, serving industries such as: Medical/healthcare OEM manufacturing Transportation/automotive Government/military Industrial upholstery Each customer's project receives: Extensive sewn, ...

Our dedicated team of professionals is here to bring reliable and dependable products to you! At Fabri-Tech, we use our 85 years of experience to exceed your expectations. Our comprehensive process for tarps, soft luggage, pouches, and many other products are unrivaled in quality. We place emphasis on our efficient process and the highly customizable options with design. Check out our website...

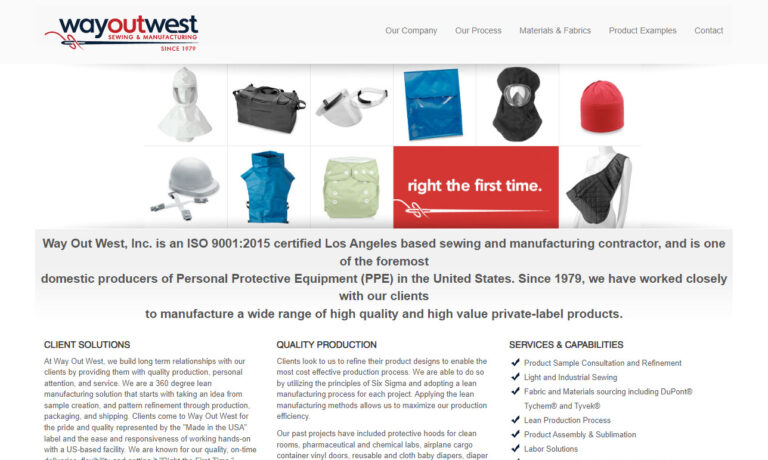

Since 1979, we, at Way Out West, Inc., have been dedicated to the art and precision of contract sewing. Our team boasts extensive expertise in various sewing processes and projects, making us a reliable partner for your diverse needs. We focus on industrial sewing production at scale, servicing the military, aerospace, medical, healthcare and safety industries. We take pride in our ability to...

At Canvasworks Inc., we provide comprehensive sewing contract services that combine craftsmanship, experience, and flexibility to meet the diverse needs of our customers. As a trusted partner to companies across a wide range of industries, we bring a collaborative approach to every project, working closely with our clients to turn concepts into high-quality finished products.

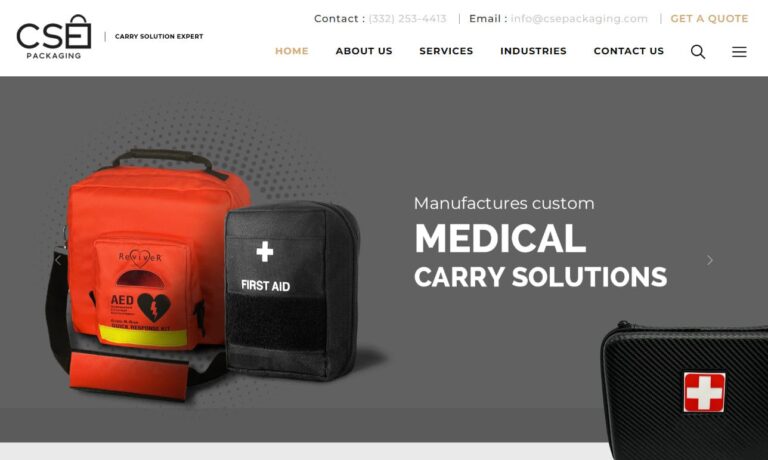

CSE Packaging, we stand as a trusted leader in the realm of custom sewn products, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

At Beowulf Industrial Sewing, we are dedicated to providing comprehensive industrial sewing solutions that meet the demands of a wide array of industries. With years of expertise and a commitment to craftsmanship, we take pride in delivering precision-driven solutions for even the most complex sewing projects. Let us bring your sewing projects to life with the precision and quality that define...

More Soft Luggage Companies

Soft luggage is often used for carry-on baggage as its adjustable shape can more easily fit in overhead bins. Most soft luggage designed for this purpose is made to fit airline size limitation guidelines. Sizes, however, are extremely variable, and large soft bags are also available. For example, large soft luggage is often used to transport exhibits for trade shows. Sporting, travel, electronic and medical industries all frequently use this flexible baggage, as do individuals. The use of backpacks, for example, is seen in schools throughout the world.

While manufacturing processes differ between companies, soft luggage always begins with a general design scheme. A computer-generated or hand-drawn design lays out the guidelines for creating bags. After a design is finalized, the fabric is measured and cut. Small or custom sewing orders may use hand cutting, while larger orders more often use automated cutting tables.

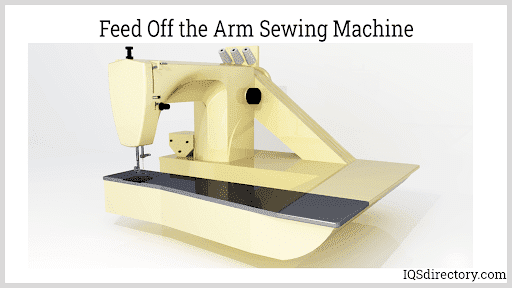

The fabric is sewn or welded together. Commercial and industrial-grade sewing machines should be used as heavy materials or thick seams may damage lower quality machines. Folded seams or foam padding between layers can be added to soft luggage to give a more definite shape and prevent the sides from collapsing inward.

Zippers or other clasps are added at this stage as well. Metal or plastic clasps, handles and frames may be added to soft luggage, though this adds weight. Most of the hardware on luggage is manufactured separately and simply applied during production. Because soft luggage lacks solid support, sturdy materials such as canvas, thermoplastic elastomers, nylon, vinyl, leather and other woven fabrics like cotton are used to provide some protection for the contents of a bag as well as to ensure its longevity. With the use of abrasion and water resistant fabrics, soft luggage offers many of the same protective abilities as hard luggage as well as some advantages over it.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services